IF PECM, THEN RUN WITH PEM TECHNOLOGIES

After years of development work, we are proud to be able to claim for ourselves that PEM Technologies is one of the technology leaders for precise electrochemical metal processing. We coined the word “Pemming” to clearly describe and differentiate this PECM technology. Development and innovation are processes we continuously press ahead with to also be able to offer our clients this quality and top results in the future.

HOW THE PROCESS WORKS

Contactless and precisely metal parts are machined using the PECM process. Between a negatively polarised tool-electrode (cathode) and a positively polarised workpiece (anode) flows an electrically conductive electrolyte: salt water. It dissolves the ionized material anodically in the machining gap between electrode and workpiece. The electrode’s shape is projected inversely onto the metal. The precise pulse current synchronized with the oscillating tool electrode and the very small working gap are the basis for the precision of this technology. The PECM process is the further development of electrochemical lowering.

Using a precise pulse current and an oscillating tool electrode enables us to create the basis for a very small processing gap. This allows for high-precision and economic manufacturing without process-related tool wear. Workpieces can be created with a reproduction accuracy and reproducibility of 2-5 μm in an absolutely contactless fashion, all without chemical agents or mechanical forces.

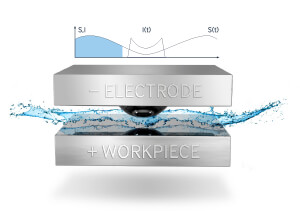

STEP 1

Open the working gap, the fresh electrolyte is fed in.

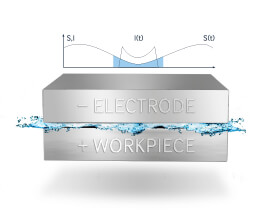

STEP 2

Close the working gap. Tool electrode (cathode) and workpiece (anode) approach each other to within a few micrometers. A controlled current pulse is triggered. At this moment, the material is anodically ablated on the surface.

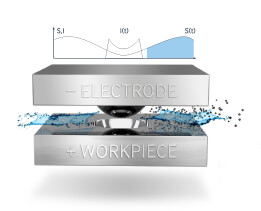

STEP 3

Open the working gap. The electrolyte is flushed out of the working gap with the ablation products.

ADVANTAGES OF THE PECM PROCESS

In comparison with conventional manufacturing technologies, our internally developed machines offer unique possibilities. Our vision and the technology make PEM Technologies machines so unusual because precision makes all the difference.

- 1

Precisely shaping nearly all metals

- 2

Metal processing irrespective of the material’s hardness

- 3

Processing of superalloys (Inconel, Hastelloy, etc.) and PM steels

- 4

Short processing times

- 5

Inexpensive process for small batches, large series, prototyping

- 6

Dimensional accuracy within the series